One-Length Golf Clubs In Canada

Are One-Length Golf Clubs for you? One-length Golf irons, are golf clubs where all irons in a set are the same length (typically the length

Take control of your game. Quality Golf Components give you the advantage of constructing a club that works with your individual swing. Mixing and matching component parts creates the total complement of clubs to support your game. By selecting lofts and club angles that work with you, the technology gains the added distance on the golf course. Need spin? No spin? Lower center of gravity or higher? More length from heel to toe, or less surface area? Heavier club? Lighter club? Drivers? Fairway Woods? Irons? At KGS-you can have it anyway you like it.

Our suppliers have created a line of drivers, fairway woods, irons and even shafts, that are forgiving, allowing for a solid hit, even with a flawed swing. They allow the average player the ability to play like a pro.Our Quality Suppliers include Pinhawk, Wishon Golf, Swing Science, Raven Golf, Enzo, Bang Golf , Krank Golf, and Star Grips. Let’s not forget the importance of assembly. Custom clubs are not only built to fit you, they are also assembled in such a way to give you the best golf your game will allow. Your club builder will assemble your Quality Golf Components to maximize each component being used. Your club builder will frequency match your entire set, Flo your graphite shafted clubs and spine align your steel shafted club. Your club builder will ensure the weights match, the grips fit and that you are happy.These are all things that you can not get off the rack at any one golf store. Be sure to see a custom club builder to improve your golf experience!

There have been many articles written, and many questions asked about custom fitting! Golf magazine published an article in the February 2011 issue with the results of their independent custom fitting test. Their findings published on page 64 are…..

From Golf Digest, Nov’09, p.28

| Q. | What is the best tip you would give to a beginner? (Anne Patterson, Boulder, CO) |

| A. | Find clubs that fit you. It will save you a ton of aggravation from the start. Make sure they aren’t too short, long or heavy. Otherwise, you’ll adapt your swing to the equipment in a way that might not be technically sound. It’s easy to get fit, and it really does matter. |

We have been saying this for years and now the best player in the world Validates our recommendations!

We use specialized equipment to locate the “spine” of a golf shaft.Shaft spines have been defined in a number of ways…they have been called irregularities; high or low spots; out of round places…the list goes on and on. A good working definition of a spine would concern the position of the shaft in a club that allows the shaft to bend naturally as it was designed to do. Shafts installed with their spines in the neutral position (parallel to the target) permit a club to perform consistently though the set; this is evidenced by player feedback!

A best-fit shaft for a player will load and unload in a straight line in relation to the intended target. Spine Aligning helps to ensure that this will occur; shafts that are not spine aligned tend to bend either more toe-up or toe-down than will provide the best shaft plane for the golfer. Independent tests conducted by Golf Science Consultants have shown that in a small population of golfers tested, they have experienced a 20-60% improvement in their percentages of on-centre hits when using clubs that have properly fitted shafts that have been spine aligned. Do to the time involved, (added cost to manufacture), most club manufacturers do not “spine align” the shafts that are produced for the general public. Shafts are mass produced, labeled or painted and graphics added. When assembled they are installed so the graphics “Look Good”. Your spine aligned set will likely have the graphics in different positions, depending on the location of the spine! In the case of Graphite shafts our preferred method of assembly is Flat Line Oscillation (FLO). With the head dry mounted on the shaft we use a laser device to determine the optimum shaft alignment.

We use specialized equipment to locate the “spine” of a golf shaft. Shaft spines have been defined in a number of ways…they have been called irregularities; high or low spots; out of round places…the list goes on and on. A good working definition of a spine would concern the position of the shaft in a club that allows the shaft to bend naturally as it was designed to do. Shafts installed with their spines in the neutral position (parallel to the target) permit a club to perform consistently though the set; this is evidenced by player feedback! A best-fit shaft for a player will load and unload in a straight line in relation to the intended target. Spine Aligning helps to ensure that this will occur; shafts that are not spine aligned tend to bend either more toe-up or toe-down than will provide the best shaft plane for the golfer. Independent tests conducted by Golf Science Consultants have shown that in a small population of golfers tested, they have experienced a 20-60% improvement in their percentages of on-centre hits when using clubs that have properly fitted shafts that have been spine aligned. Do to the time involved, (added cost to manufacture), most club manufacturers do not “spine align” the shafts that are produced for the general public. Shafts are mass produced, labeled or painted and graphics added. When assembled they are installed so the graphics “Look Good”. Your spine aligned set will likely have the graphics in different positions, depending on the location of the spine! In the case of Graphite shafts our preferred method of assembly is Flat Line Oscillation (FLO). With the head dry mounted on the shaft we use a laser device to determine the optimum shaft alignment.

Moment of Inertia is a physical property that can be expressed as a numerical measurement. That’s not a number that is common to see (yet) in golf clubs. However, the term “moment of inertia” or “MOI” is becoming much more common in advertising and marketing by the golf club companies.

Moment of Inertia is the term applied to a clubhead’s resistance to twisting when the ball is struck. For example, your swing is a little off and you hit the ball on the toe of the clubhead. A clubhead with a higher MOI will twist less as a result of the mis-hit, creating a better chance that the ball will still go where you intended and with less loss of distance.

When referring to a set of irons, rather than a club head (ie Driver) MOI actually refers to energy required to swing the club or Ease of swinging. In other words every club in a MOI matched set, feels the same and requires the same amount of energy to swing any of the matched clubs. This is our preferred method of build. With our specialized building equipment, we can build a complete set of irons in which each club is MOI Matched.

Frequency Matching is a process by which we use an Electronic Device (Frequency Meter) to check the Butt frequency of each shaft. The frequency meter measures CPM of the shaft. The shaft is clamped into the device by the butt end, and a weight placed on the tip end. The shaft is then sprung and the movement is measure by the meter. The reading is then compared to a flex chart to determine the flex of that shaft.

We will first check the Frequency on all shafts being used to build the set (or individual club). We will determine in which order / club head each shaft will be used. When building the set the clubmaker will trim the shaft tip to achieve the desired club frequency. Trimming the tip of most shafts increases the stiffness. A properly built set will increase by 3-4 cpm as each club decreases in length by 1/2 inch.

Imagine playing a round of golf with one iron length, one swing, one ball position and being able to control your distance. Now you can, with the Pinhawk SL single length irons!

Single length irons are built to one length using heads that are the same weight and Lie Angle, only the loft changes on each iron for distance control. The advantage is one set up for all irons. Traditional irons can not be adapted for single length. the weight for each head increases as the club gets shorter and the lie angle also changes on each head.

We see the Single Length irons as being a possible consideration for golfers with a handicap from 7 and higher, for golfers with a current 5 iron clubhead speed of 85mph or lower, for golfers who struggle to hit their #3, 4, 5, 6 irons consistently well, and for golfers who simply suffer from overall inconsistency with the irons.

For more on Single length Irons see this post

Shaft flex is a very important consideration when choosing new clubs. If you get the flex of your clubs correct, you will maximize your distance and accuracy. It’s true, you may be able to adjust when you are playing an incorrect flex – but it’s best to get your flex dialed in if possible. There are no hard and fast rules as to what an incorrect flex can do to your distance and accuracy, but a common result of too flexible a shaft would be a hook, and a common result of too stiff a flex would be a slice. Too stiff of a shaft can also cause a loss of distance. Again, these results are by no means universal, but these are common results we see.

1) Get your swingspeed measured by a professional clubfitter with a launch monitor. One word of caution: Sometimes if you get your swingspeed measured on a launch monitor at a “big box” store, the results could be skewed. In an attempt to feed your ego, a launch monitor can be tweaked to yield a higher swingspeed than you are really producing. This may sell clubs, but it does you no favors. Shaft flex determination is a case where you should check your ego at the door in order to produce the best fitting results. If you do get a swingspeed number you trust, below is a very basic guideline as far as flex:

If your swingspeed is less than 70 MPH with a driver, you should use a Ladies Flex.

If your swingspeed is 70-80 MPH with a driver, you should use a Senior (or A) Flex.

If your swingspeed is 81-95 MPH with a driver, you should use a Regular Flex.

If your swingspeed is 95-105 MPH with a driver, you should use a Stiff Flex.

If your swingspeed is 105+ MPH with a driver, you should use an Extra Stiff Flex.

2) Determine which club you would use from 150 yards. If you don’t know your swingspeed and don’t want to get it checked, this can be an alternate method of determining your correct flex. Below is a basic guideline:

If you use a 3 iron or a 3 or 5 wood from 150 yards, you should use a Ladies Flex.

If you use a 4 or 5 iron from 150 yards, you should use a Senior (or A) Flex.

If you use a 6 or 7 iron from 150 yards, you should use a Regular Flex.

If you use a 8 or 9 iron from 150 yards, you should use a Stiff Flex.

If you use a PW from 150 yards, you should be on the PGA Tour – what a stud!

Are there any other factors in determining my correct flex?

Yes. One other factor in determining your correct flex would be your swing “tempo”. What is swing tempo? To put it simply, it is the intensity of the transition from your backswing to your downswing. An example of a smooth tempo, or transition, would be Ernie Els. You can see a video of his tempo here. An example of an aggressive tempo would be Nick Price; you can see that here. If you find yourself to have a smooth tempo, you may want to err on the side of a softer flex. If you believe you have an aggressive tempo, you may want to err on the side of a stiffer flex. If you are in between, then tempo may not be a factor as far as affecting a flex choice.

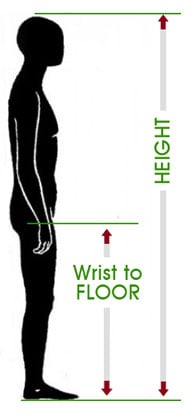

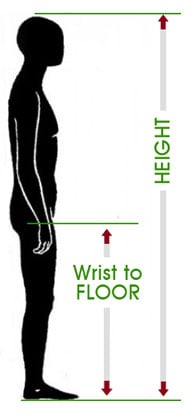

To determine what length of irons you need, you can use a simple method called “Wrist To Floor” measurement. Take a yardstick, and while standing straight with your golf shoes on, have someone measure from the floor to the crease of your relaxed wrist.

Most golfers are in the “standard length” range, which will be a measurement of 34 to 36” from floor to wrist. Here is a general chart to help choose an iron set length:

| Wrist-to-floor | Length |

| 27″ to 32″ | 36 inches |

| 32″ to 34″ | 36.5 inches |

| 34″ to 36″ | 37 inches |

| 36″ to 38″ | 37.5 inches |

| 38″ to 40″ | 38 inches |

Use the following chart to determine your single length set

| SET MAKE UP | 7 Iron Carry Distance |

| 4 iron to SW | 165 yds or more |

| 5 iron to SW | 145-164 yds |

| 5 hybrid, 6 iron to SW | 140-155 yds |

| 6 iron to SW | 130-145 yds |

| 7 iron to SW | 129 yds or less |

The length you would choose for your Driver and Fairway woods may be a different story. While you can follow the same general fitting rules as irons for length, it is not as critical. For example, someone who is 5’ 4” with a Wrist to Floor of 30”, might still prefer a standard length driver, instead of minus one inch (according to the above chart). The reason for that is, the longer a driver length is, the more distance is possible, and the lie angle (see below) is not as critical on a wood as it is an iron.

Modern standard lengths are longer than in the “old days”, since distance is often a priority for the modern golfer. The downside to a longer driver is that it is harder to control for some golfers. You’ll want to play the longest driver that you can control well. For some that is 44”, for others it can be as long as 46”. Many (like this writer) prefer a longer driver, but choose standard length in every other club. All of this is up to you and what’s best for your game. If you are unsure, just choose standard length.

Club Length:

To determine what length of irons you need, you can use a simple method called “Wrist To Floor” measurement. Take a yardstick, and while standing straight with your golf shoes on, have someone measure from the floor to the crease of your relaxed wrist.

Most golfers are said to be in the “standard length” range, which will be a measurement of 34 to 36” from floor to wrist. Here is a general chart to help choose an iron set length:

| Wrist-to-floor | Length |

| 27″ to 32″ | Minus 1 Inch |

| 32″ to 34″ | Minus 1/2 Inch |

| 34″ to 36″ | Standard Length |

| 36″ to 38″ | Plus 1/2 Inch |

| 38″ to 40″ | Plus 1 Inch |

The length you would choose for your Driver and Fairway woods may be a different story. While you can follow the same general fitting rules as irons for length, it is not as critical. For example, someone who is 5’ 4” with a Wrist to Floor of 30”, might still prefer a standard length driver, instead of minus one inch (according to the above chart).

The reason for that is, the longer a driver length is, the more distance is possible, and the lie angle (see below) is not as critical on a wood as it is an iron. Modern standard lengths are longer than in the “old days”, since distance is often a priority for the modern golfer. The downside to a longer driver is that it is harder to control for some golfers.

You’ll want to play the longest driver that you can control well. For some that is 44”, for others it can be as long as 46”. Many (like this writer) prefer a longer driver, but choose standard length in every other club. All of this is up to you and what’s best for your game. If you are unsure, just choose standard length.

What is True Length Technology™?

Can you imagine owning a set of clubs, where every club’s length

places the grip perfectly in your hands, in the same playing position every time?

“My long irons are too long and my short irons are too short“

will be a thing of the past!

TheTrue Length Technology™ secret is in the individual length progression between each club. Simply put – 1/2 inch length progression verses 1 degree of lie angle is mathematically incorrect.

True Length Technology™ corrects this condition

True Length Technology™ is a reduced length fitting methodology where the length differential between each iron is less than the traditional 1/2″ between individual clubs. A typical OEM set will have 3 1/2″ of length differential between the 4 iron and the PW whereas a TLT set will have just over 2″ of length differential. Every club is mathematically modeled keeping the player athletic for each individual club where the OEM model will have an average sized player crouching with the short irons (or palming the grip) and choking down on the long irons (or will deal with a toe up lie condition).

Traditional methods of golf club building has each club one half of an inch shorter than the next club as you progress through the set from 3 iron down to the wedges, regardless of the lie angle .

Here is an example of standard build lengths:

| Men’s & Women’s Standard Lengths | |

| Clubs | Men’s/Women’s |

| Graphite Driver | 45″/44″ |

| Steel Driver | 44″/43″ |

| 3 wood | 43″/42″ |

| 5 wood | 42″/41″ |

| 7 wood | 41″/40″ |

| 3 iron | 39″/38″ |

| 4 iron | 38.5″/37.5″ |

| 5 iron | 38″/37″ |

| 6 iron | 37.5″/36.5″ |

| 7 iron | 37″/36″ |

| 8 iron | 36.5″/35.5″ |

| 9 iron | 36″/35″ |

| PW | 36″/35″ |

| SW | 36″/35″ |

Although this has been an accepted method for years, the golfer is forced to adjust setup / address position for each club in the bag.

True Length Technology™ on the other hand, will use a club length the best fits your address position and increases based on a mathematical calculation to give you the same address position regardless of which club that you have in your hands.

One common hand position, relative to a perfectly math modeled length and lie will result in:

True Frequency Technology ™

Frequency matching is a term quite often used by club builders so lets start with a basic understanding of Frequency as it relates to golf clubs.

Frequency – Measured with specialized equipment in Cycles Per Minute (CPM) relative to a known beam length.

Butt Frequency – Clamped at the end of the thickest section or grip end. This is the stiffest portion of the shaft and is primarily related to the players swing speed. A faster swing speed would benefit from a stiffer butt section.

Mid Frequency – Re-clamped in the mid section or zone. This section is primarily related to the Players Tempo. A quicker Tempo would benefit from a stiffer mid section.

Tip Frequency – Re-clamped again only in the tip section (short beam length). This section is primarily related to the Release. The later the Release the stiffer the tip section should be.

True Frequency Technology ™ – is a high level Shaft Sorting Program we use, aimed at simplifying, finding and defining the ‘Overall Frequency’ of a full set of RAW shafts. Data is compiled in 5″ increments for up to 13 shafts (a complete set). Butt frequency tells such a small part of the story.

The TFT Sort Engine automatically averages, sorts and assigns the Stiffest overall shaft profile to the longest club. This allows the overall weakest shaft to be tipped the most – stiffening it to the greatest degree. Sorted graphs display each increment and its associated Frequency – but the Overall Average is what determines the True Flex.

This is true Frequency Matching!

Most club builders will only use the Butt Frequency to build your set of clubs, this is good, but really does not tell the whole story of the shafts relative stiffness or how it will actually play.

For the complete True Length Technology™ story visit the inventor at

Dan’s Custom Golf Shop

True Length Technology™ and

True Frequency Technology TM

are Registered Trademarks of Dan’s Custom Golf Shop

Are One-Length Golf Clubs for you? One-length Golf irons, are golf clubs where all irons in a set are the same length (typically the length

Wishon EQ1-NX Single Length Irons The Wishon EQ1-NX Single Length Irons are a popular choice for golfers looking for consistency in their iron play.

Overall, single length golf clubs can simplify the game for many players, offering a more straightforward approach to improving consistency and performance.

We are all about easier ways to increase your enjoyment on the golf course. If we can help you make golf simpler then you are going to get great enjoyment from the results.

905-567-4422 / 416-726-4285 (M) Mail@ Info@Konagolfsales.Com

The Dover Coast, Port Dover, Ontario, N0A 1N3

Copyright © 2025 Kona Golf Sales – (a division of 971691 Ontario Limited). All rights reserved.

Our Store / Shipping will be closed for the season thru to Mid April .

Thank you for your Patronage.

If you wish to place an order to reserve an in-stock item, please Contact Us Here and we will follow up.

Sorry for any Inconvenience!